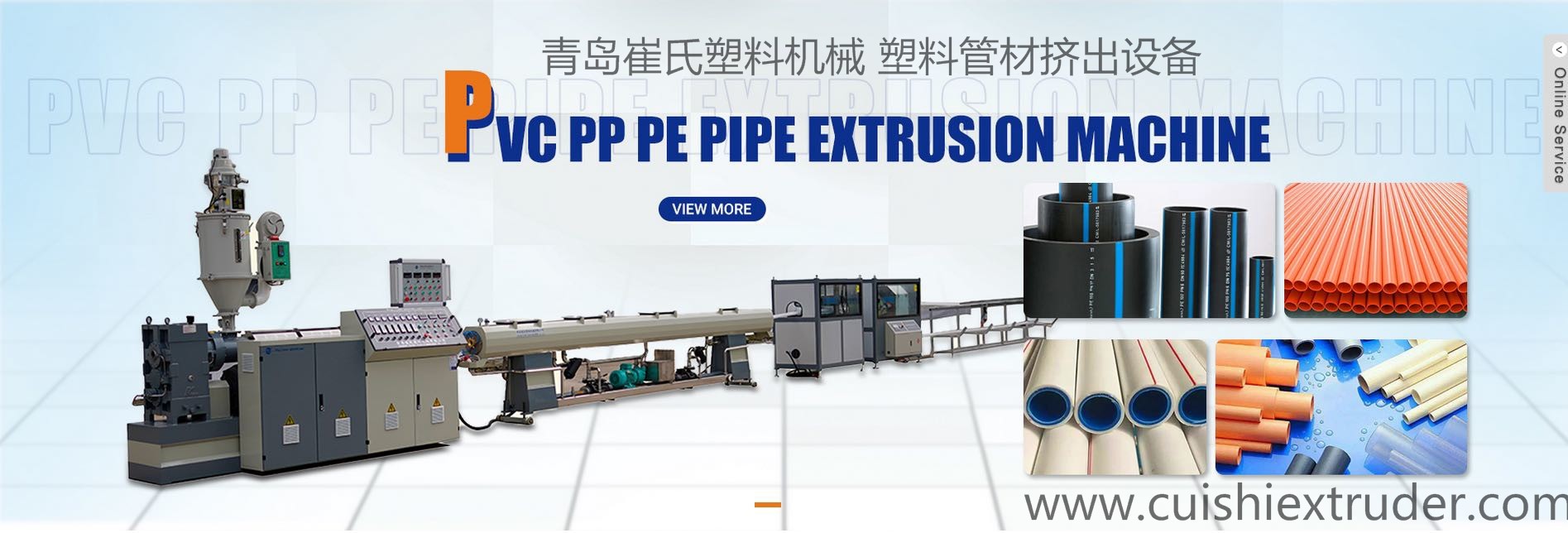

HDPE ọkpọkọ extrusion mmepụta akara

40-160mm MPP Pipe Electric Tube Plastic Single Screw Extruder Machine Production Line

| Mba. | Aha | Ọnụọgụ |

| 1 | Otu ịghasa extruder na akpaka nri ngwaọrụ | 1 set/2 nkeji |

| 2 | Akpụkpọ anụ | 1 setịpụrụ |

| 3 | Vacuum calibrating na tankị jụrụ oyi | 1 set/2 nkeji |

| 4 | Wepụ igwe | 1 setịpụrụ |

| 5 | Igwe nchacha | 1 set/2 nkeji |

| 6 | Stacker | 1 setịpụrụ |

1.40-160mm MPP Pipe Electric Tube Plastic Single Screw Extruder Machine Production Line Single ịghasa extruder na akpaka nri ngwaọrụ.

(1) Akara moto: Siemens ma ọ bụ akara china ndị ọzọ ama ama

(2) ika inverter: ABB/DELTA/SINEE

(3) akara kọntaktị: Siemens /DELTA

(4) Akara agbagharị:Omron/DELTA

(5) ika agbaji: Schneider/DELTA

(6) Usoro ikpo ọkụ: seramiiki ma ọ bụ nkedo

2.40-160mm MPP Pipe Electric tube

Plastic Single Screw Extruder Machine Production LineVacuum calibrating na mmiri jụrụ oyi tank

(1) Ike mgbapụta oghere: 4kw

(2) Ike mgbapụta mmiri: 4kw

(3) Ihe: igwe anaghị agba nchara

(4) Usoro: Ịfesa mmanye

(5) Dayameta: ahaziri

(6) Ogologo tankị: 6 m

A na-ejikarị SJ Series Single Screw Extruder hazie PP, PE, PPR, ABS na plastik ndị ọzọ.Ejiri igwe inyeaka, ọ nwere ike rụpụta profaịlụ, ọkpọkọ, mpempe akwụkwọ na ngwaahịa plastik ndị ọzọ na granulation.Nke a Single Screw Extruder nwere uru nke usoro teknụzụ mmepụta dị mfe, mmepụta dị elu, ịdị mma kwụsiri ike na ọnụ ala dị ala. Kwesịrị ekwesị maka ihe dị iche iche polyolefin: HDPE, PPR, PP, na ABS wdg.

Isi uru

1.Ụdị ọkpọkọ a nwere ọtụtụ uru, dị ka ọkụ na-eguzogide corrosion, dị mfe idozi, ogologo oge iji wdg.

2.A na-ejikarị ọkpọkọ eme ihe n'ụzọ dị elu, ụlọ ọrụ obodo, ụlọ na ihe ndị ọzọ.

Ahịrị usoro

Raw material+ Master Batches → Mixing → Vacuum Feeder → Plastic Hopper Drier → Single screw extruder →Co-extruder for color string & Multi Layers → Mold → Vacuum Calibration Tank → fesa mmiri jụrụ oyi → Mwepu → Enweghị uzuzu uzuzu → Ugboro abụọ / Single diski Winding/ Stacker → Nyocha ngwaahịa ikpeazụ & mbukota

Anyị na-agbaso ụdị azụmahịa nke Germany dị ka onye na-ebubata eriri plastic extrusion zuru ụwa ọnụ.Anyị enyelarị ihe karịrị ahịrị 1000 dị n'ọtụtụ mba n'ihi na anyị na-enye teknụzụ kachasị ọhụrụ, igwe ruru eru, akụrụngwa a pụrụ ịdabere na ya na ọrụ ire ere.

Chepụta ma rụpụta igwe dabara adaba maka gị.

2. Tupu nnyefe, anyị ga-anwale igwe ruo mgbe afọ juru gị kpamkpam.(Ị nwere ike ịbịa n'ụlọ ọrụ anyị iji nyochaa ahịrị mmepụta na-agba ọsọ.)

3. Nnyefe.

4. Anyị ga-enye mgbe-ahịa ọrụ:

(1) Nrụnye na nhazi ubi;

(2) ọzụzụ ọzụzụ ndị ọrụ gị;(3) Ọrụ nlekọta na nrụzi ubi;

(4) Akụkụ mapụtara n'efu;

(5) Nkwado nka na ụzụ vidiyo/N'ịntanetị.

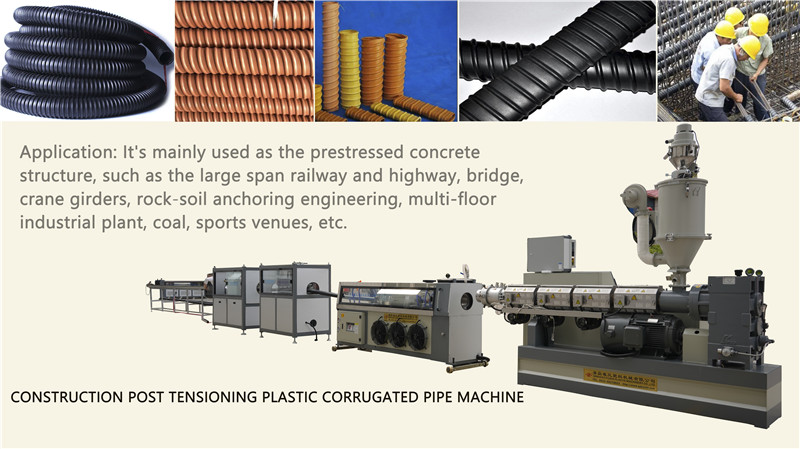

Plastic tube eletriki waya nchebe ọkpọkọ ike USB conduit MPP ike ọkpọkọ eme igwe