plastic pe anwụrụ ahịrị 110mm 315mm 630mm hdpe ọkpọkọ eme igwe si emeputa

QINGDAO CUISHI Plastic Machinery CO., LTD e hiwere na 1999. Ahụmahụ mmepụta bụ tozuru okè na ọgaranya.N'ime ha, ọ na-ebupụ ihe karịrị afọ 24.Ụlọ ọrụ mmepụta ihe nke ụlọ ọrụ anyị na-ekpuchi ihe karịrị 30,000 square mita., na ahụmahụ elu-edu mkpara otu, mbụ klas ngwá, zuru okè na irè àgwà mmesi obi ike usoro, elu na zuru ezu ule ngwá.

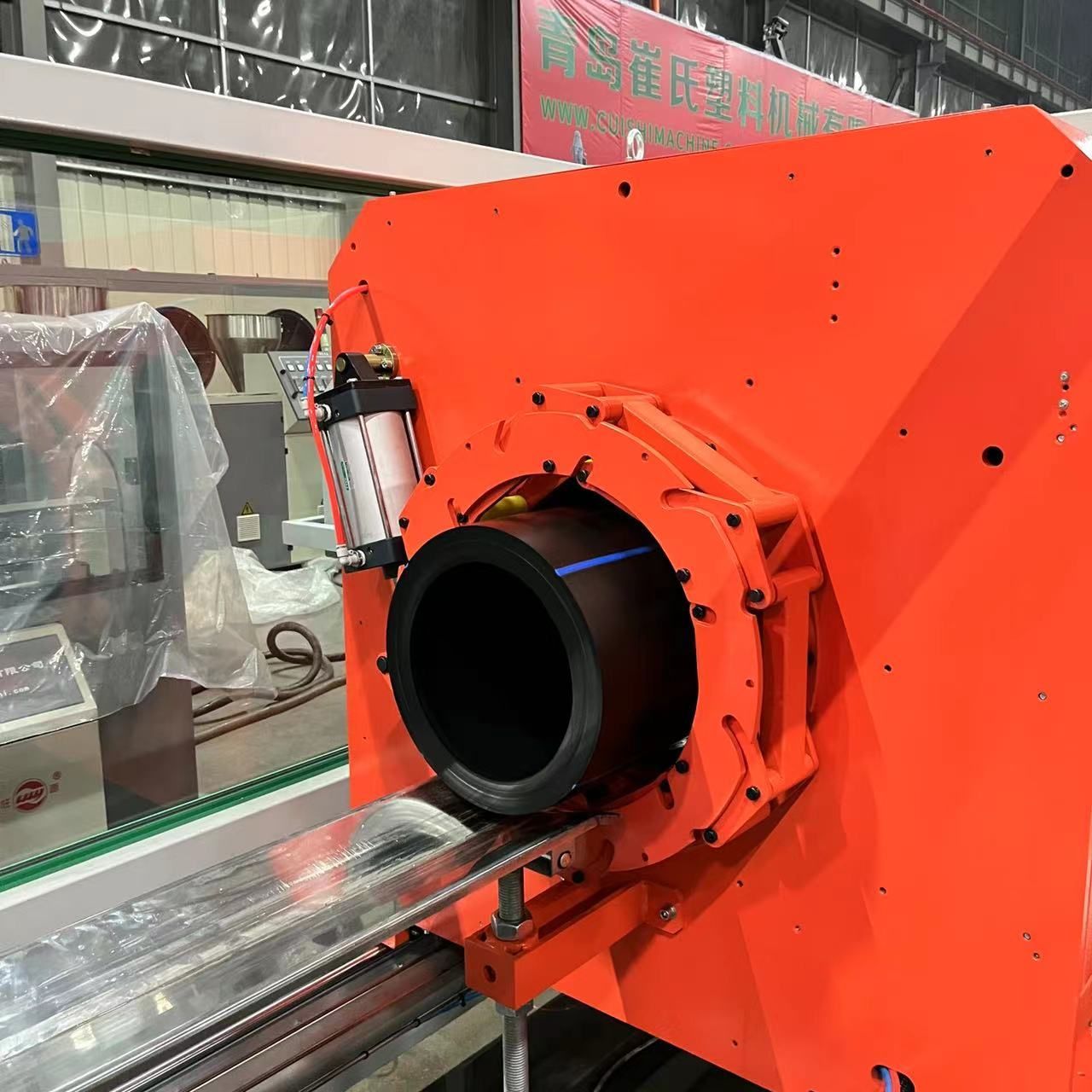

PE Pipe Extrusion Line.

20mm 110mm 315mm 630mm 800mm 1200mm 1600mm plastic pe anwụrụ extruder na-eme ka mmepụta akara / igwe

315mm LDPE HDPE PE ọkpọkọ eme igwe / mmepụta ahịrị / extruder igwe maka mmiri na gas

ahaziri 315mm PE HDPE LDPE Pipe Ime Machine Plastic Pipe Extrusion Production Line

Site ogologo oge na-aga n'ihu ọhụrụ na ule, Qingdao cuishi emepụtala ọgbọ ọhụrụ Pee ọkpọkọ extrusion akara na elu akpaaka, elu na-agba, elu pụrụ ịdabere na, ala ike oriri.Anyị PE ọkpọkọ extrusion nwere ike hazie dịgasị iche iche nke ihe onwunwe, gụnyere HDPE, LDPE, PP, PPR, PPH, PPB, MPP, PERT, wdg

Anyị PE ọkpọkọ extrusion akara nwere ike na-emepụta si size nke kacha nta 16mm ka 2000mm nwere otu oyi akwa ma ọ bụ multi-layer.

1.Otu ịghasa Extruder.

1.1Simens Touch Screen na PLC

1.2 gburugburu Ọdịdị nke Barrel

1.3 Pụrụ iche iche nke ịghasa

1.4 Igwe ọkụ seramiiki jụrụ oyi

1.5 igbe igbe dị elu

Dabere na 38: 1 L / D ruru maka ịghasa imewe, anyị emepụtala 38: 1 L / D ruru.E jiri ya tụnyere 33: 1 ratio, 38: 1 ratio nwere uru nke 100% plasticization, na-abawanye mmepụta ikike site 30%, belata ike oriri ruo 30% na iru fọrọ nke nta linear extrusion arụmọrụ.

2.Extrusion anwụ Isi.

2.1 Ngwaọrụ na-ebugharị nke isi anwụ

2.2 Die Head Rotary Device

2.3 Ngwaọrụ na-ekpochapụ ọkụ

2.4 Ngwaọrụ jụrụ oyi maka Core

2.1Extrusion anwụ isi tinye gburugburu Ọdịdị, onye ọ bụla ihe eruba ọwa na-enịm evenly.Ọwa ọ bụla na-esote ọgwụgwọ okpomọkụ na polishing mirror iji hụ na ihe na-aga nke ọma.Ọdịdị isi anwụ bụ kọmpat ma na-enyekwa nrụgide kwụsiri ike, mgbe niile site na 19 ruo 20Mpa.N'okpuru nrụgide a, àgwà ọkpọkọ dị mma na mmetụta dị ntakịrị na ikike mmepụta.Nwere ike ịmepụta otu oyi akwa ma ọ bụ ọkpọkọ multi-layer.

3.Vacuum tank.

3.1 Ike dị jụụ maka Calibrator

3.2 Nkwado ka mma maka ọkpọkọ

3.3 Onye na-agbachi nkịtị

3.4 Valve enyemaka nrụgide

A na-eji tankị Vacuum na-akpụzi ma mee ka ọkpọkọ dị jụụ, ka o wee ruo nha ọkpọkọ ọkọlọtọ.Anyị na-eji nhazi ụlọ okpukpu abụọ.Ụlọ nke mbụ dị n'ogologo dị mkpụmkpụ, iji hụ na ọ na-arụ ọrụ oyi na agụụ.Dị ka calibrator na-etinye n'ihu nke mbụ ụlọ na ọkpọkọ udi na-etolite tumadi site calibrator, a imewe nwere ike hụ na ngwa ngwa na mma akpụ na mma nke ọkpọkọ.

4.tankị jụrụ oyi.

4.1 Ngwaọrụ ejigide ọkpọkọ

4.2 Mmiri tank mmiri

4.3 Ogo fesa nozzle

4.4 Ngwaọrụ Na-emezi Nkwado Pipe

4.5 Ngwaọrụ Nkwado Pipe

A na-eji tankị jụrụ oyi mee ka ọkpọkọ dị jụụ.

5Wepụ unit.

5.1 Ngwaọrụ ejigide ọkpọkọ

5.2 Mmiri tank mmiri

5.3 Ogo fesa nozzle

5.4 Ngwaọrụ Na-emezi Nkwado Pipe

5.5 Ngwaọrụ Nkwado Pipe

5.6 PIPE CATERPILLER anọ na-ebupụ

Ịkwụ ụgwọ na-enye ike traction zuru oke iji dọpụta ọkpọkọ kwụsie ike.Dị ka dị iche iche ọkpọkọ nha na ọkpụrụkpụ, anyị ụlọ ọrụ ga-ahazi traction ọsọ, ọnụ ọgụgụ nke claws, irè traction ogologo.Iji hụ na ngwa ngwa extrusion ọkpọkọ na-akpụ akpụ, zerekwa nrụrụ ọkpọkọ n'oge traction.

6.CUTTER

6.1 Ngwaọrụ Mkpuchi Eluigwe na Ala

6.2 Ndozi elu etiti

6.3 Hụrụ na Agụba Na-agbanwe Maka 110-315MM Ọ BỤGHỊ UWU UWU

Cutter nke Siemens PLC na-achịkwa, na-arụkọ ọrụ ọnụ na-ebupụ unit iji nwee igbubi nke ọma.Onye ahịa nwere ike ịtọ ogologo ọkpọkọ

ha chọrọ ịkpụ.Multi-na-eme omume maka mmezu nke otu usoro ịkpụ (chebe agụba na nkwọ, gbochie agụba.

na nkwọ rapaara n'ihi na oké ọkpọkọ na bee ihu ọkpọkọ bụ ezigbo).

WINDER nwere ike ịgbanye 110mm