Ụlọ ọrụ QINGDAO CUISHI Plastic Machinery Co.,Ltd

Granulator

Ihe nrụpụta dị elu dị elu na-ekpo ọkụ plastik pellet / ọkpọkọ / cubeextruder igwe eji emegharị ihe eji emegharị ihe

SJ usoro otu ịghasa extruder plastic igwe tumadi emetụta extrude PP, PE, PET, PVC, ABS, PS, PA ect material.It ịmụta pụrụ iche gia igbe, na nwere atụmatụ nke ala mkpọtụ, kwụsiri ike na-agba ọsọ, elu ibu ikike, ogologo ọrụ ndụ. .N'ịbụ onye dị iche iche na-emepụta ihe na ihe inyeaka, ọ nwere ike ịmepụta ọkpọkọ plastik, mpempe akwụkwọ, osisi, granules na ihe ndị ọzọ.

| oru ngo:DJ85 otu ịghasa ahịrị pelletizing | |

| Akụrụngwa & usoro | Ihe nkiri PE |

| Ngwaahịa ikpeazụ | PE granules |

| Ike mmepụta | 120-200kg / h , dabere na njirimara ihe onwunwe. |

| Central elu | 1.14m |

pp pepelletizing ahịrị rọba ihe eji emegharị granulating igwe na-emebi emebi plastik granules na-eme igwe

Oke(CSUsoro nke okpukpu abụọ Compactor-Granulator):

| Model(ogbo okpukpu abụọ) | CS85-100 | CS100-120 | CS130-150 | CS160-180 | CS180-200 |

| Dayameta ịghasa (mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Ike(kg/h) | 150-200 | 300-350 | 500 | 600-700 | 800-1000 |

Ngwa:

PE, ihe nkiri PP, silk, flakes (≤0.5mm), akpa, wdg.

Mara, CS usoro compactor granulator anyị nwere ike ịbụ ụzọ ịkpụ warara, ma ọ bụ ụzọ ịkpụ mgbanaka mmiri maka nhọrọ

Ihe mejupụtara:

Belt ebu(ihe nchọta igwe) → Compactor → Main extruder(vacuum degassing system) → Hydraulic screen changer → Sub-extruder →

Ihe na-agbanwe ihuenyo hydraulic → Sistemụ mbelata mgbanaka mmiri → Igwe mmiri na-eme mmiri → sistemu ikuku ikuku → nchekwa nchekwa → kọbọd njikwa

- ozi izugbe

1.1Oghere ala

Ihe owuwu ntọala, ọrụ ala, ọrụ mgbidi kwesịrị ka onye na-azụ ahịa rụchaa nke ọma maka ịnakwere ahịrị pelletizing a.

Onye na-azụ ahịa kwesịrị ịnye kreenu, forklift ma ọ bụ ihe ndị ọzọ na-ebuli elu, ihe mgbago na ngwaọrụ.

Mpaghara: a ga-ahazi dịka nhazi ahịrị si dị.

1.2Ịnye ọkụ

Ike arụnyere:106KW (oriri ike bara uru ga-abụ ihe ruru 70%)

Ịnye ọkụ:

Voltage na-enye: 3*380V+N+PE;

Nkwenye voltaji: + 10%/-5%;

Voltaji njikwa: 24VDC+220VAC;

Ugboro: 50Hz+-2%

Waya / eriri:

- Wires / eriri sitere na ọkụ ọkụ iji chịkwaa kabinet (nke onye na-azụ ahịa nyere).

- Igwe ọkụ eletrik niile sitere na kabinet njikwa ruo igwe ọ bụla (onye na-azụ ahịa nyere).

1.3Mmiri mmiri

Oriri0.6T/h (mmiri recycles)

Mmiri jụrụ oyi:

Na-enweghị mgbaze ma ọ bụ kwụsịtụrụ mineral dị ka phosphor, sọlfọ, ígwè, wdg.

Okpomọkụ mbata T1: max.15 ℃

Okpomọkụ ọpụpụ T2: T2=T1+5℃

Nrụgide ntinye, min: 2.5 mmanya

Isi ike: 5-8ºdH;

Reflux: enweghị nrụgide

Ọdọ mmiri:

Site na ntinye mmiri na igwe ọ bụla (nke onye na-azụ ahịa nyere).

1.4Ikuku akpakọbara:0.6M3/min, 0.4 ~ 0.7Mpa

1.5Ndị ọrụ na-arụ ọrụ

2-3 Ndị mmadụ

1.6Mmanu mmanu mmanu

Enwetara na ahịa mpaghara na nkwenye nke onye na-ere ahịa (nye site n'aka onye na-azụ ahịa).

- Usoro azụmahịa

2. 1Machine ndepụta & Price

| Mba. | Aha ngwaọrụ | Nlereanya | Qty(nhazi) |

| 1 | ebufe eriri |

| 1 |

| 2 | Compactor |

| 1 |

| 3 | DJ85/33single ịghasa extruder | DJ85/33 | 1 |

| 4 | Ụdị efere ihe ngbanwe ihuenyo hydraulic160 |

| 1 |

| 5 | Usoro ịkpụ mgbanaka mmiri |

| 1 |

| 6 | Igwe na-ekpochapụ ihuenyo na-ama jijiji |

| 1 |

| 7 | Silo |

| 1 |

| 8 | Eletrikikabinet |

| 1 |

2.2Usoro ịkwụ ụgwọ

- 40% dị ka nkwụnye ego site T / T.

- 60% dị ka itule site T / T tupu nnyefe na mgbe nnyocha.

2.3Oge Mbuga ozi

N'ime ụbọchị ọrụ 50 site na ụbọchị ịnata nkwụnye ego.

2.4Nkwakọ ngwaahịa

Ihe nkiri plastik.

2.5Akwụkwọ ikike

Ọnwa 13 maka akụkụ igwe site na ụbọchị nke ụgwọ nbinye.Nkwa ọnwa atọ maka ihe ọkụ eletrik ma ọ bụrụ na ọkụ eletrik na ụlọ ọrụ Buyer adịghị eguzosi ike.

cuishi ga-ana onye na-azụ ahịa ọnụ ahịa ihe mapụtara mgbe akụrụngwa enweghị akwụkwọ ikike wee nye ntuziaka teknụzụ ogologo oge.

2.6Nwụnye & Nrụpụta

- Onye na-azụ ahịa kwesịrị ịdị njikere maka nrụnye mgbe akụrụngwa rutere, dị ka ọkụ, mmiri, ọrụ na cranes, wdg.

- cuishi ga-akwado maka ngwa visa maka ndị injinia, ndị ga-aga ụlọ ọrụ Buyer maka ọrụ inye ọrụ.

- Onye na-azụ ahịa kwesịrị ị nweta tiketi ụgbọ elu njem njem maka ndị injinia ma ọ bụrụ na akwadoro ngwa visa, ma na-akwụ ụgwọ ndị dị ka usoro visa, nri, ebe obibi na ikike nke USD100 kwa ụbọchị maka injinia ọ bụla.

2.7Nkwenye

- 60 ụbọchị site na nkwuputa ụbọchị.

3.Nkọwa nka na ụzụ

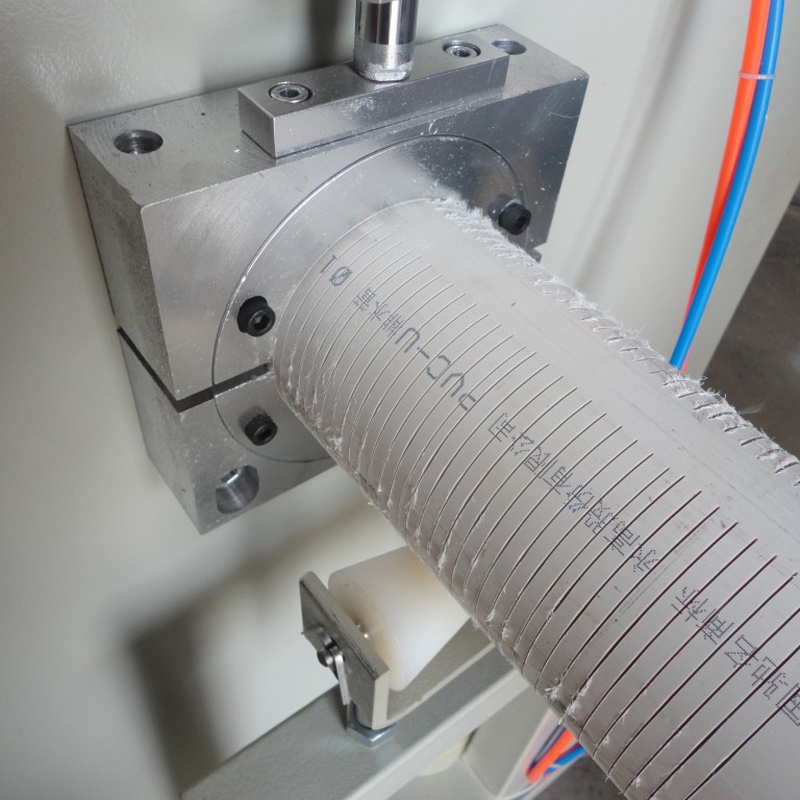

3.1DJ85 Single ịghasa extruder

5Usoro ịkpụ mgbanaka mmiri

agụba na anwụ, na nrụgide nke mma na-akpaghị aka gbanwee hụ na edo ọnwụ ike nke mma. Malite usoro ahụ na otu igodo iji mee ka arụ ọrụ nke usoro dum dịkwuo elu adaba; Ọkpụkpọ ihu anwụ kwụ ọtọ Ike nke cutter:2.2kw Ike nke mgbapụta mmiri: 2.2kw The cutter bụ ugboro akara site inverter | |

| 6 | Igwe na-ekpochapụ ihuenyo na-ama jijiji |

Ihuenyo na-ama jijiji dị elu jikọtara ya na ihicha centrifugal kwụ ọtọ nwere ike nweta arụmọrụ ihicha dị mma yana obere ike oriri.cuishi na-anabata imewe mechiri emechi ma nwee mkpuchi mkpuchi ụda, nke nwere obere mkpọtụ ma bụrụ enyi na enyi.

Ike moto: 0.25kw*2. Akụkụ ndị na-akpọtụrụ mmiri: SUS304. Gbakọta sieves: ọ bụghị welded.Awụnyere na ofu site na kposara, maka adaba dochie sieves ọhụrụ n'ọdịnihu. Mmiri na-agba ya gburugburu na rọba, iji gbochie site na nnukwu njupụta ọdịiche kpatara oge opupu ihe ubi. Nhazi pụrụ iche iji gbochie obere adịghị ọcha ịdaba na mgbapụta mmiri.

Ike moto: 3kw. Rotary ọsọ: 1460rpm Akụkụ na-akpọtụrụ mmiri na granules: SUS304. | |

| 7 | Silo |

| Ike dị irè: 700LIhe nke akụkụ na kọntaktị na ihe igwe anaghị agba nchara | |

| 8 | Eletrikikabinet |

Usoro njikwa na-anabata Siemenscontrol, ma kwadebere ya na ihuenyo mmetụ aka nke ụlọ ọrụ mmepụta ihe (ihe nhọrọ)

Dị ka usoro ezi uche nke setịpụrụ na usoro nhazi ihe achọrọ, usoro cuishi jikọtara na-achọpụta mmalite otu isi, si otú a na-ezere mmejọ na usoro mmalite akwụkwọ ntuziaka.

Site n'enyemaka nke otu ahaziri ahaziri ahazi, sistemu cuishi nwere ike ghọta mmechi otu igodo nke modul sistemu niile iji zere mmebi akụrụngwa kpatara n'ihi ọrụ na-ezighi ezi n'oge mmechi ntuziaka.

cuishi nwere ọrụ nkwụsị mberede mberede, nke a na-eji dị ka ihe mberede maka ihe ize ndụ ndị a na-ejighị n'aka n'oge arụ ọrụ nke igwe, na-emechi usoro dum ngwa ngwa na ngwa ngwa iji zere ihe mberede nke abụọ na mmerụ ahụ.

Ngwaọrụ nchekwa ndụ Usoro cuishi na-eburu n'uche nsogbu nchekwa nke akụrụngwa n'oge arụ ọrụ.Ebe ọ bụla na-arụ ọrụ na ọnọdụ akụkụ na-agbanwe agbanwe na-eji ihe nchekwa ọkụ eletrọnịkị iji hụ na nchekwa nke akụrụngwa mgbe a na-arụ ọrụ ma zere ihe egwu nwere ike ime n'oge arụ ọrụ nke akụrụngwa iji merụọ ndị na-arụ ọrụ ahịa.

Site n'enyemaka nke usoro njikwa okpomọkụ ziri ezi na atụmatụ kachasị mma ezubere iche nke ngalaba usoro plasticizing, usoro cuishi nwere ike hụ na a pụrụ ịdabere na ya na nkwụsi ike nke pelleting ikpeazụ.

Site n'enyemaka nke ụkpụrụ njikwa modular na cognition zuru oke nke ịrụ ọrụ nke ihe eji emegharị ihe dị iche iche, sistemu cuishi nwere ike hụ na ihe mkpofu a na-emezi na-enweta ọnọdụ preheating kacha mma na mkpirisi n'ime ụlọ compaction, ma nwee ike zere ihe ndọghachi azụ plastik ka ọ ghara ịgbakọ. .Oke ikpo ọkụ ma ọ bụ mmebi n'ime ụlọ nkwakọba ihe. Onye kọntaktị: Schneider Mgbasa ozi: CHNT Mgbanwe izugbe: CHNT Ihe mgbawa sekit: CHNT Mara: Ndị ahịa kwesịrị ịnye waya site na kabinet njikwa na igwe ọ bụla.

|

3.2 Akụkụ mapụtaras: FOC

Akụkụ igwe

| No | Aha | Nkeji | Qty |

| 1 | Ọkụ na-ekpo ọkụ | iberibe | 2 |

| 2 | Ngwá ọrụ iwepụ ihe nkedo | setịpụrụ | 1 |

| 3 | Asbestos uwe aka | ụzọ abụọ | 1 |

| 4 | Ntinye na ntinye akara mmanu mmanu | setịpụrụ | 1 |

| 5 | Vacuum O-mgbanaka | iberibe | 2 |

Akụkụ eletrik

| No | Aha | Nkeji | Qty |

| 1 | AC kọntaktị | iberibe | 1 |

| 2 | Bọtịnụ | iberibe | 2 |

| 3 | Tebụl okpomọkụ | iberibe | 1 |

| 4 | Thermocouple | iberibe | 2 |

4.Inspection tupu nnyefe

Onye na-ere ahịa na-ahụ maka ịhazi ọsọ ule tupu nnyefe.